Control Each Drop

Transparency counts more than ever these days.

Transparency counts more than ever these days.

Checking the current fill level and temperature directly from the means of transport brings security and transparency to your warehouse and delivery inventory.

SECU IntelliTank is designed for these tasks.

SECU IntelliTANK Advertisement

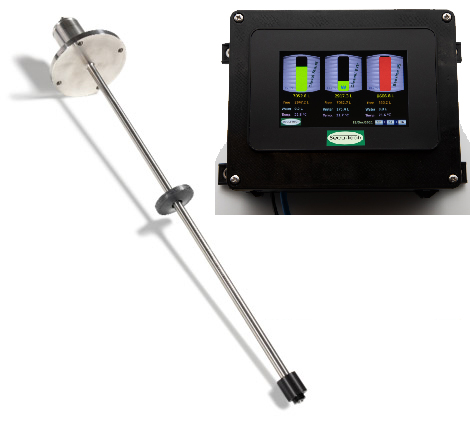

The vibration-resistant TORRIX Mobile sensor measures liquid product parameters continuously, transmitting data to the Intellitank controller and a remote cloud server. Pre-defined geo-fencing points restrict the truck driver from travelling outside the route, ensuring exact delivery at defined locations.

The vibration-resistant TORRIX Mobile sensor measures liquid product parameters continuously, transmitting data to the Intellitank controller and a remote cloud server. Pre-defined geo-fencing points restrict the truck driver from travelling outside the route, ensuring exact delivery at defined locations.

SECU IntelliTANK

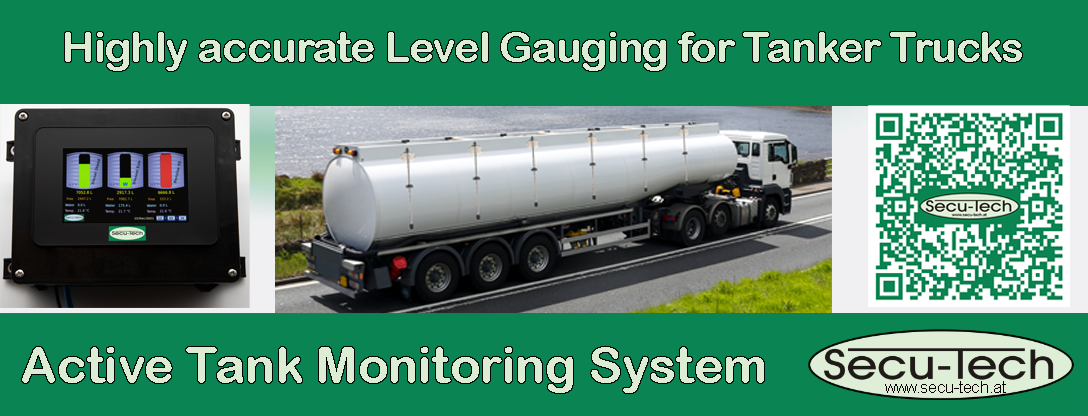

Complete system for Level Gauging with data transfer, local Display and Output Module for tanker-trucks.

The local Display shows up to 10 tanker-truck compartments or tanks as well as high/low level alarms. The contents are shown temperature compensated with the possibility of connection for external alarms

The local Display shows up to 10 tanker-truck compartments or tanks as well as high/low level alarms. The contents are shown temperature compensated with the possibility of connection for external alarms

Gilbarco Vedder Roots refers about SECU Intelli Tank in the Mining Industry

We see up to 50% of our customers of well dispens from these mobile tanker and when a single mobile tanker can hold up to 600000 l it fuel stock it is critical which control and record activities.

We ensure only authorized refilling willing take place. Added to this your vehicle location solution hip tabs on where your mobile tanker is with active GEO zoning driver management and if desired live camera feats and when we tie this you get full usibility and tight control over your fueling activities from the mobile tanker.

Gilbarco have to advice you do just that our mobile tank leveling solution provide "realtime stock levels" across your mobile fleet ensuring you have visibilty of your mobile stock on hand at all time. coupled with our mobile tanker control and meter solution all together for you on an easy to use dashboard in our size reporting plattform you get a comprehensive and complete end to end solution to manage your mobile fleet by implementing our solution you ensure control efficiency and saving all your operations.

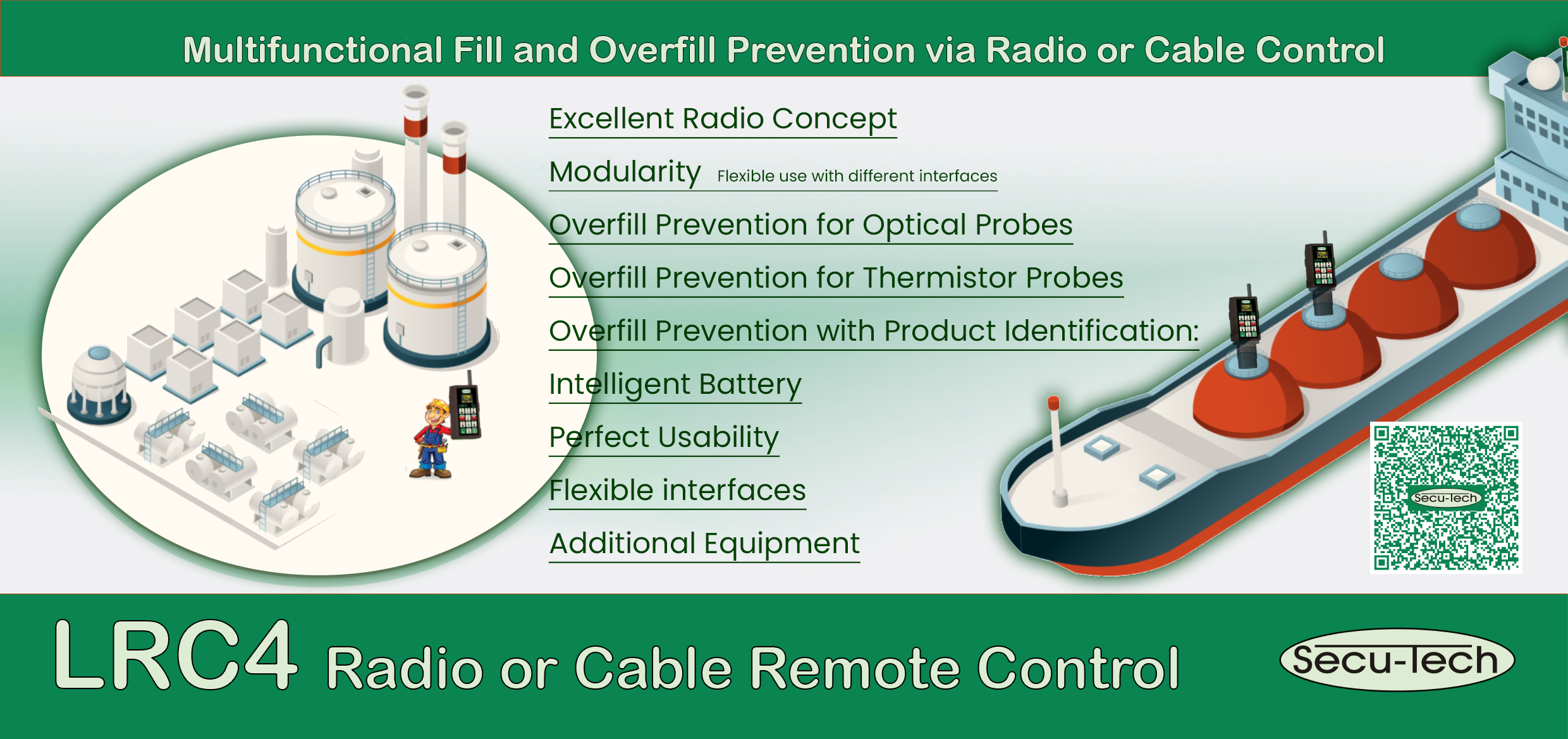

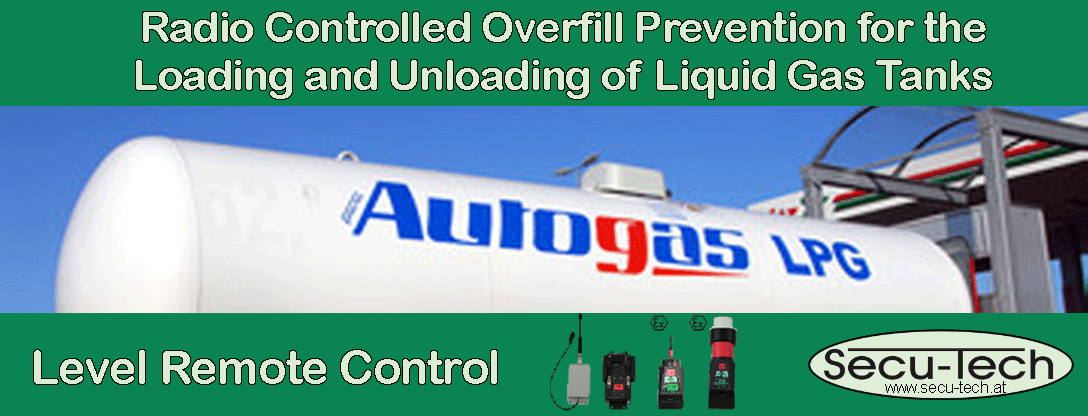

Level Remote Contol / LRC 4 / Overspill Prevention

Further development of the very successful LRC 3

LRC 4 masters all remote control devices for a problem-free loading and unloading process on ships and at bunker stations.

Efficient processing through the use of radio - compared to the lengthy cable overfill protection - gives the loading and unloading process more security and faster processing is guaranteed.

Secu-Tech celebrates its 20th anniversary

Dear employees, valued customers and partners,

We look back with pride on two decades of successful business activity. It was and is a time full of challenges, successes, growth and, above all, solidarity. Together we have achieved milestones over the last 20 years that have made our company what it is today.

The journey began two decades ago with a vision, a team of committed people and the belief in success. Since then, we have been through ups and downs together, driven innovation, conquered our place in markets and, most importantly, worked together as a family.

In these 20 years, we have not only developed products and services, but also built relationships - relationships with customers, partners and, above all, with everyone here in the company. Our success is based on trust, integrity and continuous development.

We would like to thank each and every one of us - the employees who do their best every day, the customers who put their trust in us, the partners who work with us and everyone who has contributed to our success.

The future looks bright and we are ready for the next 20 years and beyond. With a strong team, clear goals and the will to continue delivering excellence, we are confident that the coming years will be as successful as the past.

Here’s to the next 20 years! Together we will continue to grow, learn and succeed.

Thank you for your support and commitment.

With kind regards

Dagmar Höckner-Schallmeiner

Secu-Tech on the bunker ship at the port of Hamburg

Customer visit at the port of Hamburg. A supply ship equipped with Secu ship bunkering equippment was visited by Mrs.Dagmar Höckner-Schallmeiner and Mr.Werner Denk at the beginning of February. The system has been running for several years and is an important detail on the ship to prevent overfilling when refueling other ships.

Customer visit at the port of Hamburg. A supply ship equipped with Secu ship bunkering equippment was visited by Mrs.Dagmar Höckner-Schallmeiner and Mr.Werner Denk at the beginning of February. The system has been running for several years and is an important detail on the ship to prevent overfilling when refueling other ships.

Advertisement at ERPEC News

Our newest Advertisement at Erpec News Secu Tech Advertisement

Our newest Advertisement at Erpec News Secu Tech Advertisement

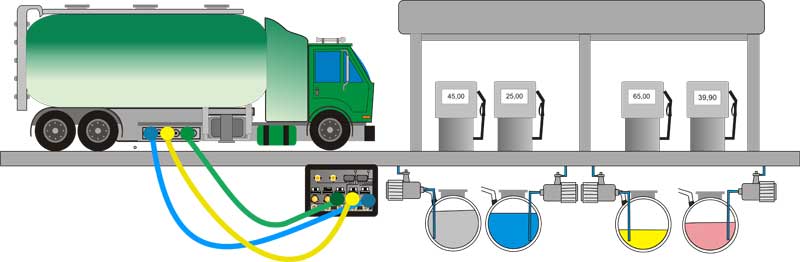

Downstream Efficiency

As important as it is to avoid product mix and overfill into tank truck compartments and fuel stations, it is also very important to make sure that the amount and quality of fuel stays the same from the time it has been loaded until it arrives at the fuel station. Secu-Tech provides a comprehensive data management system of the whole logistic chain in real time.

As important as it is to avoid product mix and overfill into tank truck compartments and fuel stations, it is also very important to make sure that the amount and quality of fuel stays the same from the time it has been loaded until it arrives at the fuel station. Secu-Tech provides a comprehensive data management system of the whole logistic chain in real time.

Deadman system for hazardous zones and products

Deadman and/or Easy Deadman configurable

Deadman time is configurable (e.g.: 30 sec.; 1min, 2min, 4min,...)

ATEX hand-held transmitter with ATEX battery

EMERGENCY stop possible at any time

Additional remote control functions (e.g. speed change,...)

Long range

Acoustic and visual warning on the hand-held transmitter (when the dead man's time has expired)

LRC4 "Product Information"

LRC4 - next generation of SECU-TECH GmbH overspill prevention and overfill protection

Find out more about all the advantages of the new LRC4 and the enormous range of possible uses to protect against accidents, pollution and environmental damage.

Sales Meeting in Salzburg: Products & Innovations

Visit us in Salzburg. We look forward to welcoming you to the international meeting.

Visit us in Salzburg. We look forward to welcoming you to the international meeting.

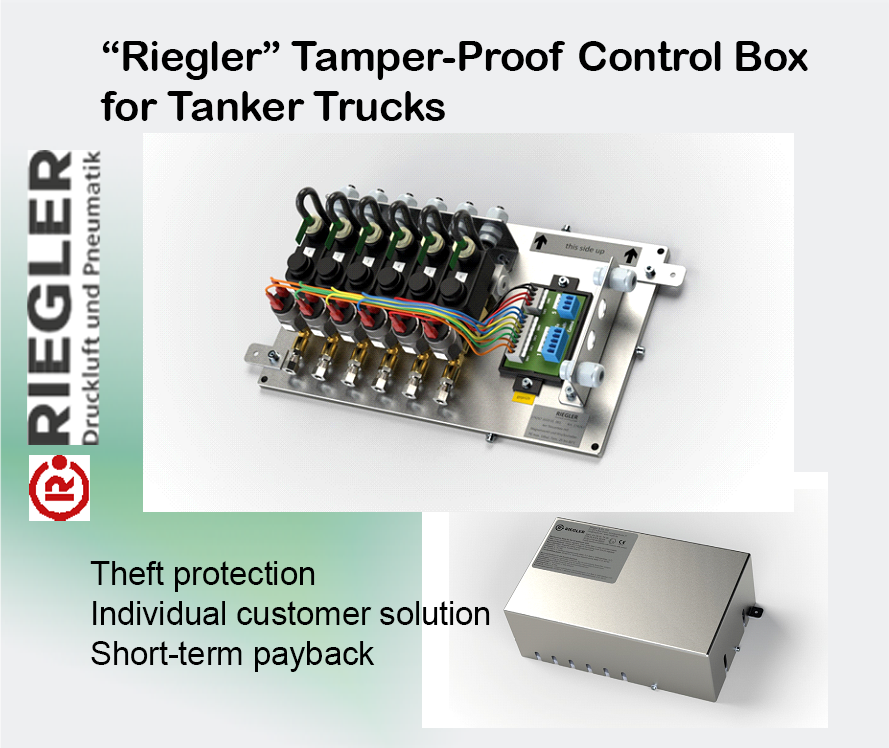

Tamper-proof tanker control box

The tamper-proof control box for tankers includes a control unit that is used to transmit control signals to solenoid valves. These solenoid valves switch the drain valves of a tank. Sensors are assigned to the floor and collector valves, which record the actual switching status of the valves. The control unit compares the pressure switch signals with the control signals and detects any discrepancies. If this occurs, an event signal is issued.

Stationary Overfill Prevention for non-EX Applications – thermistor based

Easy installation due to a 2-wire connection to the transducer

Easy installation due to a 2-wire connection to the transducerTorrix Mobile & SecuTank DATA & Truck Monitoring

Tank truck monitoring:

Highly accurate, continuous level measurement (product and water)

Programmable alarm messages

Local display + truck monitoring with email alerts

Local display without truck monitoring with local alarms

Graphics, statistics, historical data

Configuration changes can be migrated remotely

Data integration into existing systems possible.

Stationary Overfill Prevention "EX AREA"

Thermal level sensor - overfill protection in the Ex area. The thermal limit switch (with ATEX approval) protects storage tanks with potentially explosive liquids from overfilling. The maintenance-free thermal level sensor can be easily installed in all tanks. Fast and precise, reliable, durable.

Thermal level sensor - overfill protection in the Ex area. The thermal limit switch (with ATEX approval) protects storage tanks with potentially explosive liquids from overfilling. The maintenance-free thermal level sensor can be easily installed in all tanks. Fast and precise, reliable, durable.

Downstream Efficiency

Next to the importance that product mix into compartments of

tanker-trucks and product mix as well as overfill into fuel stations

need to be avoided, the control of the product during transport, too

be sure, that the exact amount and quality of what has being loaded

at the depot arrives at the fuel station, becomes more and more

important. Combined with a comprehensive data-management

information of the complete logistic chain is provided in real-time

and location for mineral-oil companies and hauliers.

Torrix Mobile + SecuTank Data + Tank Monitoring

Mobile Solutions for Tanker-Trucks

Mobile Solutions for Tanker-Trucks

Level Gauging in Tanker-Trucks and for other mobile Applications with Data Transfer

Complete system for Level Gauging with Data Transfer for Tanker-Trucks

The system measures the level and the temperature of the product high accurate and continuously and sends this to the Tank Monitoring Data Management Program for analyses, evaluation and information for the customer, including high- and low-level alarms as well as alarms on unusual losses (theft control).

Combined with GPS- and Geo-Fence, tour tracking and route plannings are possible.

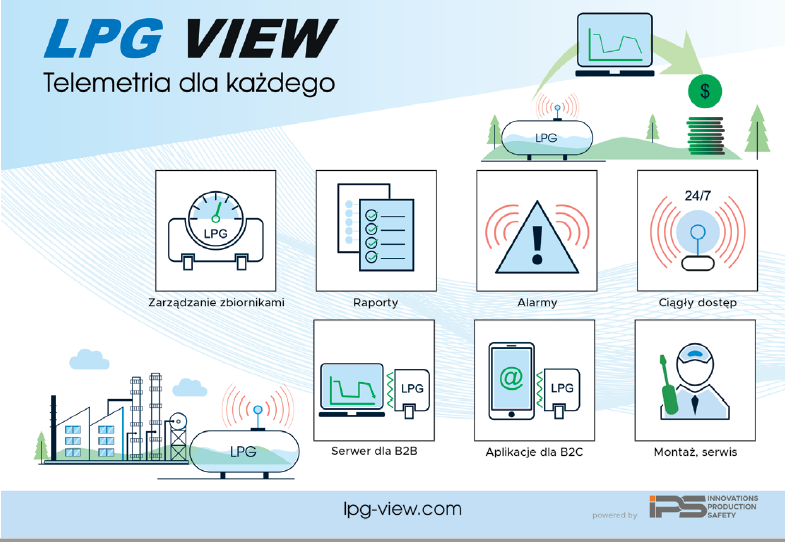

Liquefied gas tank monitoring using telemetry

Liquefied gas tank monitoring using telemetry

Absolute security on filling for

Absolute security on filling for